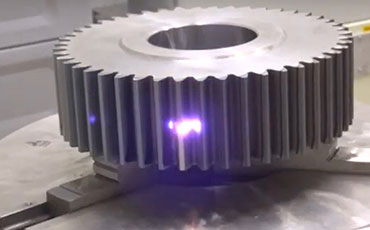

Automatic/Robotic Laser Surface Hardening

Working Principle : Laser Surface Hardening is a new material surface treatment technology developed in last few years. The principle of laser surface hardening is based on the strong penetrating ability of laser. When the metal surface is heated to the critical transition temperature below the melting point, it austenite rapidly, then quenches rapidly by self-cooling to form fine-grained martensite, thus obtaining a hardening layer HRC3-5 with higher hardness than traditional quenching, thus greatly improving the wear resistance and service life of work piece.

Enquire NowWe Adopt The Most Advanced Semiconductor Laser Technology :

Till now, laser surface hardening is dominated by high power industrial CO2 laser, which is characterized by high laser power (up to 10 kW) and low manufacturing cost. However, it has obvious disadvantages, such as poor stability of laser power, high failure rate of equipment and high quality of quenching small workpieces. The stability is poor. Therefore, high power CO2 laser cannot meet the needs of laser quenching of clamp.

With the continuous development of high-power semiconductor laser technology, kilowatt-level semiconductor lasers have been gradually applied in industry. Compared with CO2 lasers, the wavelength of semiconductor lasers is shorter (840 or 980 microns), and the absorption rate of metal to laser is as high as 30-70%. The laser power is stable and the dynamic adjustment is convenient.

Therefore, using semiconductor to process metal workpieces has the following remarkable advantages:

- There is no need to absorb and brush the surface of the workpiece. Semiconductor quenching is a completely clean quenching process without any pollution to the workpiece, environment and operators.

- The laser power can be adjusted well. The temperature of the treated workpiece is measured by sensors and fed back to the laser. Then the laser power is adjusted to achieve complete closed-loop control. This ensures the stability of the surface heating temperature and quenching quality of the treated workpiece, especially for the high-precision laser quenching of small workpieces. Laser power stability is good and maintenance is simple.

- It can be seen that the semiconductor laser is the most advanced technology in the world to process the clamp. Through Mechatronics manufacturing and control, a set of fully automatic laser quenching equipment for nippers is produced, which can solve the process problem of nippers strengthening and meet the demand of high quality treatment for nippers.

Customized Laser Surface Hardening Systems

We provide Customized Laser Surface Hardening Systems as per the application , as per the parts / products to be hardened.

The complete system consists of following Parts :

- Semiconductor Fiber Laser Source

- Water Cooling System

- Focusing System

- 3 Axis CNC Work Station

- Monitoring and Alignment System

- Temperature Detection and Feedback Control System

- Series of Fixtures, Overall CNC system, etc.

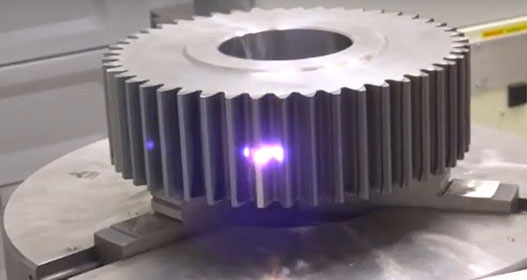

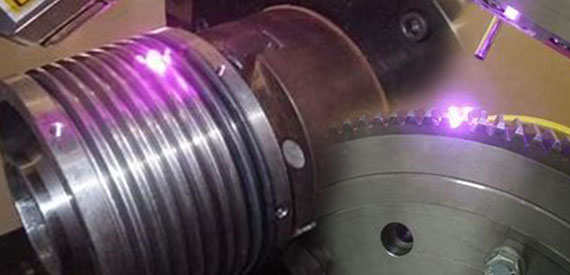

Working Principle of the System

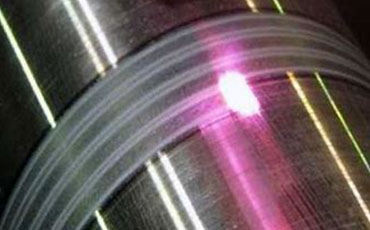

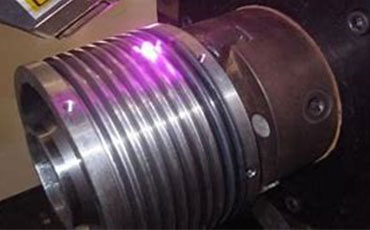

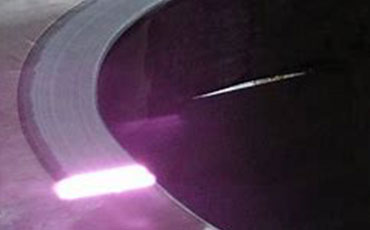

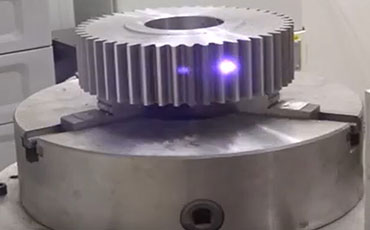

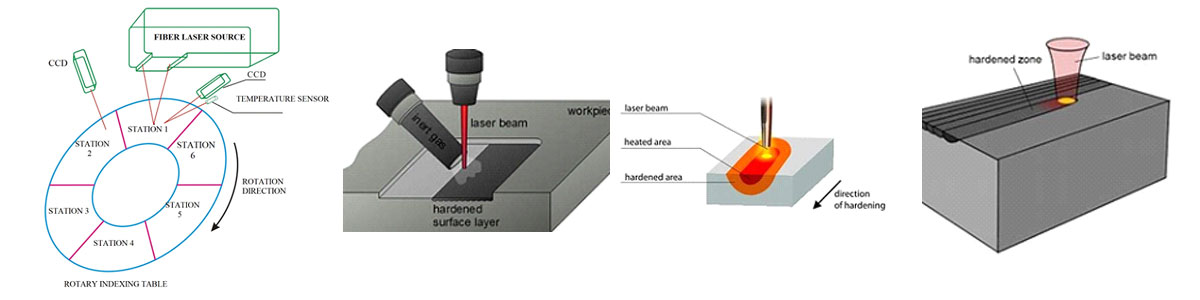

The schematic diagram of laser processing is shown in above pictures & figures. In this scheme, six station machine tools are used to handle the parts. The major functions are as follows:

- Laser intensification processing station, which includes product fixture, temperature sensor, CCD monitoring system and laser processing system (laser can be controlled by three axese

- Image recognition processing work station, which includes product fixture, CCD image recognition and positioning system, in a closed area;

- Workpiece to be processed position, which includes product fixture, in the operation area;

- Loading and unloading work station, which includes product fixture, is in the operation area.

TECHNICAL SPECIFICATIONS

1. Laser Source

| Laser Power | 2000 W CW |

| Wavelength | 808nm±10nm @25ºC |

| Spectral Width | <8nm (FWHM) |

| Threshold Current | <13A |

| Operation Current | <85A |

| Operation Voltage | <60V |

| Ratio of electricity to light | >30% |

- 2. Machining Machine Tools

- 3. CNC System

- 4. Detection and Positioning System

- 5. Feedback Control System for Temperature Detection

- 6. Optical System : The focusing system of semiconductor laser is 370 mm in focal length and 6 *12 mm in spot size.

7. Water Cooling System

| Cooling Power | Cooling Power: >5000w (at 25°C water temperature and 35°C ambient temperature) |

| Temperature control range | 15℃-30℃ |

| Ambient temperature | 10℃-42℃ |

| Flow rate | >15l/min at 4 bar |

| Water connector | 4x1”outer diameter |

| Electricity data | 400V3PH50Hz |

8. Laser Power Supply

| Input | AC 3 Phase, 48-62 Hz, 380VAC |

| Output voltage | 0-30V |

| Output current | 0-100A |

| Manual Control Panel |

9. Laser Hardening Parameters

Laser hardening of the closed edge (material 50CrV and 60CrV) is carried out. The strengthened width of the single edge is more than 2 mm, the depth of the layer is more than 2 mm, and the hardness of the edge is more than HRC62.

Advantages of our Laser Surface Hardening Systems

- Customized Designs as per Application

- Accurate & Precise

- Very Fast & Cost Effective

- Rapid Cooling through Self Quenching

- Cooling Medium Not Needed

- Less Material Distortion

- Completely Clean Quenching Process Without Any Pollution to the Workpiece, Environment and Operators

- Hardening Possible at Atmospheric Conditions Without Protective Gas

- Hardening Possible on Grooves, Cutting Edges, Guide Ways, etc.

- Temperature Detection Feedback System – To Harden Cutting Edges or Small Work Pieces Without Fear of Melting

- Hardness Penetration Depths about 0.5-0.8 mm, On Some Material up to 2 mm (Depends Upon Laser Power, Material Volume, etc)

- Laser Power Stability is Very Good

- Maintenance is Simple

SAMPLE APPLICATIONS