Fusion Edge Laser Machines

Featuring up to 120 IPS (3.05 m/s) engraving speeds, 5g acceleration, and a variety of wattage configurations, the Fusion Edge Laser Series from Epilog can help you boost your productivity and expand your product offerings.

Comprised of the Fusion Edge 12, 24, and 36, all the machines in the Edge Series feature Epilog’s revolutionary IRIS™ Camera Registration System that gives laser operators a real-time image of the engraving table so they can quickly and accurately position their artwork on even the most uniquely shaped items.

Systems in the Fusion Edge Series can engrave and cut a variety of materials including wood, acrylic, fabric, cork, rubber, slate, glass, and so much more. Additionally, these easy-to-use laser machines include a 7-inch LED-lit touch display, trace capabilities at the laser, as well as SAFEGUARD™ features that keep the mechanics of your laser cleaner than ever.

Enquire Now| Fusion Edge 12 | Fusion Edge 24 | Fusion Edge 36 | |

| Work Area |

24" x 12" x 7"

(610 x 305 x 178 mm) |

24" x 24" x 10"

(610 x 610 x 254 mm) |

36" x 24" x 10"

(914 x 610 x 254 mm) |

| Laser Options | CO2 or Fiber | CO2 | CO2 |

| CO2 |

30, 40, 50, 60 watts

|

30, 40, 50, 60, 80 watts | 50, 60, or 80 watts |

| Fiber | 30 watts | - | - |

| IRIS™ Cameras | 1 overhead | 2 overhead | 2 overhead |

Features: Benefits of Epilog’s Fusion Edge Laser System

The Fusion Edge laser engraving and cutting machines from Epilog Laser combine our top-of-the-line technology and our latest features in three formats: a compact desktop machine with the Fusion Edge 12, the mid-size Fusion Edge 24, and a larger standalone system with the Fusion Edge 36 - all leveraging over three decades of laser machine design and manufacturing experience to create powerful and truly modern systems.

Highest-Speed Engraving

IRIS™ Camera Positioning

Touch Screen at the Laser

Engineered and Manufactured in the USA

Network Your Laser Across Your Business

SAFEGUARD™ Features

Air Assist

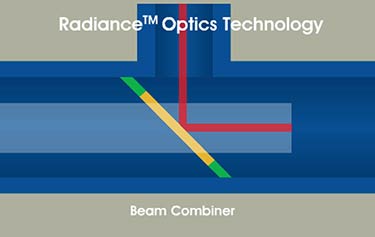

Radiance™ Beam Enhancing Optics

CO2 Waveguide Laser Tubes by Epilog

1 GB Memory in the Machine

Long-Life Steel Bearing

Epilog Fusion EDGE Technical Specifications

| Fusion Edge 12 | Fusion Edge 24 | Fusion Edge 36 | |

|---|---|---|---|

| Work Area | 24” x 12”

(610 x 305 mm) |

24” x 24”

(610 x 610 mm) |

36” x 24”

(914 x 610 mm) |

| Maximum Z-Depth | 7” (178 mm) | 10” (254 mm) | 10” (254 mm) |

| Laser Tube Wattage |

CO2 - 30, 40, 50, or 60 watt

Fiber - 30 watt

|

CO2 - 30, 40, 50, 60, or 80 watt

|

CO2 - 50, 60, or 80 watt

|

| Software | Epilog Laser Software Suite: Laser Dashboard™ & Epilog Job Manager™ | ||

| Memory | Multiple files, up to 1 GB total. Engrave any file size. | ||

| Operating Modes | Optimized Raster, Vector, and Combined modes | ||

| Motion Control | High-speed, continuous-loop, brushless DC servo motors using rotary encoding technology for precise positioning | ||

| X-Axis Bearings | Ground & polished stainless steel, Teflon-coated, self-lubricating bearings. | ||

| Belts | Advanced B-style double-wide Kevlar precision drive belts. | ||

| Resolution | Fully-flexible and user-controlled from 75 – 1200 dpi | ||

| Optional Lenses | 1.5" or 4.0" | ||

| Speed and Power | 120 IPS (3.05m/s) with 5G acceleration. Computer-controlled in .001 increments up to 100%. Color mapping feature links Speed, Power, Frequency, and Raster/Vector mode. | ||

| Print Interface | USB, Wireless, and 10Base-T Ethernet. Windows 7/8/10 compatible. | ||

| Size (W x D x H) | 39.5” x 26.5” x 17.9"

1003 x 673 x 455 mm |

41.52” x 32.81” x 38.04"

1055 x 834 x 967 mm |

53.52” x 32.81” x 38.04"

1359 x 834 x 967 mm |

| Weight | 138 lbs (63 kg) | 225 lbs (102 kg) | 260 lbs (117 kg) |

| Electrical | 110 to 240 volts, 50 or 60 Hz, single phase | ||

| Ventilation | 350-400 CFM (595-680 m3/hr) external exhaust to outside or internal filtration unit required. One output port, 4" (102 mm) diameter. | ||

| Safety | Class 2 Laser Product – 1 mW CW MAXIMUM 600 – 700 nm | ||

Epilog Fusion Edge CO2 Material Compatibility

| Engrave | Cut | |

| Wood | ||

| Acrylic | ||

| Fabric | ||

| Glass | ||

| Coated Metals | ||

| Ceramic | ||

| Delrin | ||

| Cloth | ||

| Leather | ||

| Marble | ||

| Matte Board | ||

| Melamine | ||

| Mother of Pearl | ||

| Paper | ||

| Mylar | ||

| Pressboard | ||

| Rubber | ||

| Wood Veneer | ||

| Fiberglass | ||

| Painted Metals | ||

| Tile | ||

| Plastic | - | |

| Cork | ||

| Corian | ||

| Anodized Aluminum | ||

| Stainless Steel | * | |

| Brass | * | |

| Titanium | * | |

| Bare Metals | * | |

| * CO2 lasers will mark bare metals when coated with a metal marking solution. For more information, visit our laser metal marking page. | ||

| Do you have a material you would like us to test? Our Applications Teamwould be happy to assist you. | ||